Projects

Challenges that we enjoyed solving

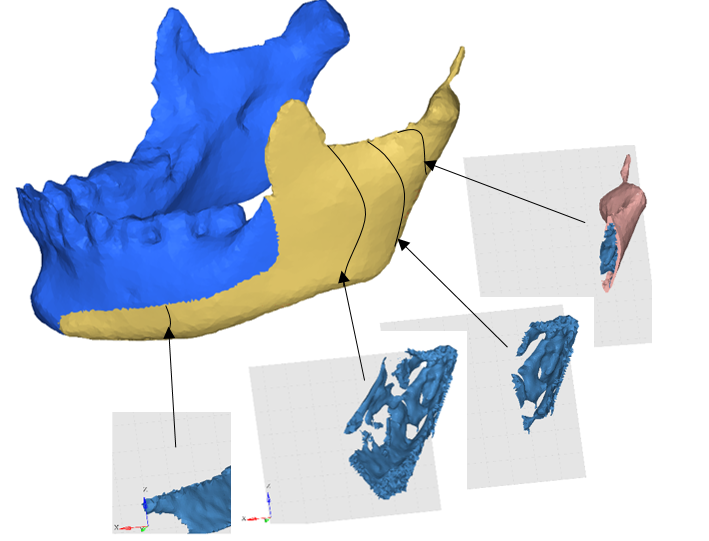

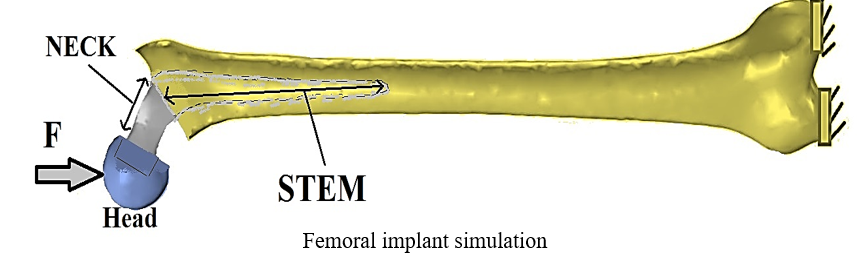

Bone is considered the hard part of the body which is responsible for protecting and supporting the body. It is a highly complex composite material with a lot of variance in component and composition within the body itself. The bone may suffer external stress causing fragmentation of bone, as motorcycle incidents, and so on; or physiological disorder, making normal stresses able to destroy the bone as a hip joint fracture in aged women. Designing artificial body parts to help to heal or replace permanently damaged organs is a challenge for physicians and engineers. The way of approaching the problem will vary, with the designer's experience and way of thinking. Mostly there are two ways of thinking in the matter of orthopedic design; the strictly Engineering aspects, and the medical aspect. These two ways of thinking are corporate and mutate to develop good orthopedic that satisfy the patient's needs. Bone grafting is used in some cases. Due to the limited resource regarding patient living bone, synthetics materials may use, however, the fatigue life and failure under static and dynamic load is a risk. Metal implants are one of the good choices in such matters. Such treatment was traced to the ancient Egyptians 4000 years ago. Recently, materials used for bone implant extended from metallic to advance ceramics and reinforced polymers. But still, metallic alloys are considered as one of the important options.

The most important aspect of long-term metallic implants is body rejection due to stress shielding. Stress shielding occurs when metal implants, such as bone plates and screws, are used to repair fractures or in joint replacement surgery. Although rigid metal plates stabilize the fracture, help maintain contact between bone fragments, and allow early weight-bearing and patient mobility, the higher stiffness of the implant results in bone loss as a result of decreased physiologic loading of the bone. As a result, the implant dislocates and fails its purpose.

This is prescribed as the following: - the Osseointegration between the bone and the orthopedic starts to deteriorate with time, such that the bone is dissolving exposing the orthopedic.

Heuristic and metaheuristic structural optimization techniques were investigated and increasingly used in structural design. Optimization is used intensively in the structural layout designing process especially after the shift of the mathematical analysis method from the direct approximation of exact solution (infinite series usage) to numerical discrete representation, which was the key to introducing modern computers to aid the engineers in the hideous design process. One of the most popular and reliable discretization numerical methods is finite element analysis, which is adopted in this work.

In the beginning, structural optimization addressed a simplified form of layout designing problem with the least design variables possible by parametrized the problem in terms of spatial or characteristic perimeters, therefore; It is named parametric optimization. Parameters such as member size in frame design usually used for heat sink design.